Windhager BioWIN2 on pellets 38-63 kw

Power: 38-63kw

Control: LED panel, phone app

Energy class: A+

Efficiency at rated load: 93%

A compact choice among large pellet boilers

The integrated ash box ensures long ash removal intervals

Small space requirement, only 1.12 m²

Large fuel tank approx. 111 kg for pellets enables long and uninterrupted burning phases

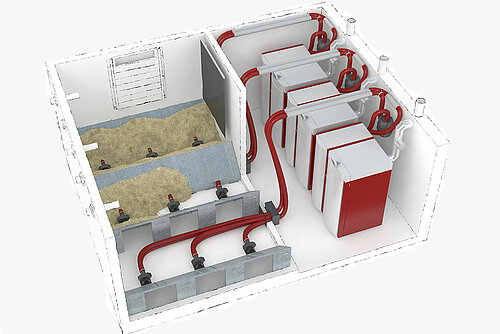

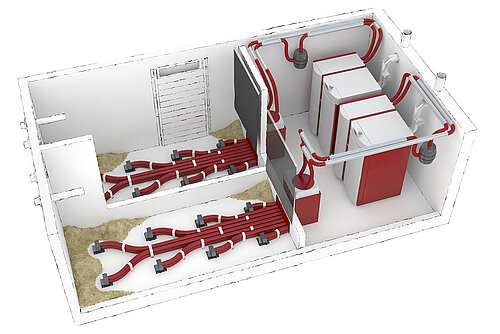

The cascade control system, specially developed by Windhager, constantly checks how many boilers and which boilers need to work to ensure the required amount of heat. A balanced use of the system is also ensured by checking the working hours. Thanks to its considerable modulation depth, the BioWIN2 38-63 kW cascade works very efficiently even at a lower output range.

Compared to large boiler systems, the cascade system is extremely reliable: if one device does not heat up, you can continue heating with the other device as usual. And maintenance work can be done without turning off the heating.

Technical data

| Type | Unit | BWE 382T | BWE 502T | BWE 632T |

| Rated heat output range | kW | 10.8 – 38 | 14.9 – 49.9 | 18.2 – 63 |

| Efficiency at rated load | % | 92,3 | 92,9 | 93,6 |

| Tank capacity | kg | 111 | ||

| Installation dimensions, boiler body (Width x Depth x Height) | mm | 790 x 975 x 1750 | ||

| Installation dimensions, fuel tank (LxWxH) | mm | 1221 x 624 x 506 | ||

| Net weight | kg | 850 | ||

| Boiler body weight | kg | 647 | ||

| Flue gas connection diameter | mm | 150 | ||

| Electricity consumption (part load/nominal load) | W | 37 / 96 | 42 / 114 | 50 / 141 |

| Energy efficiency class | A+ | |||